What is the present valuation and projected CAGR of the hot runner temperature controller market?

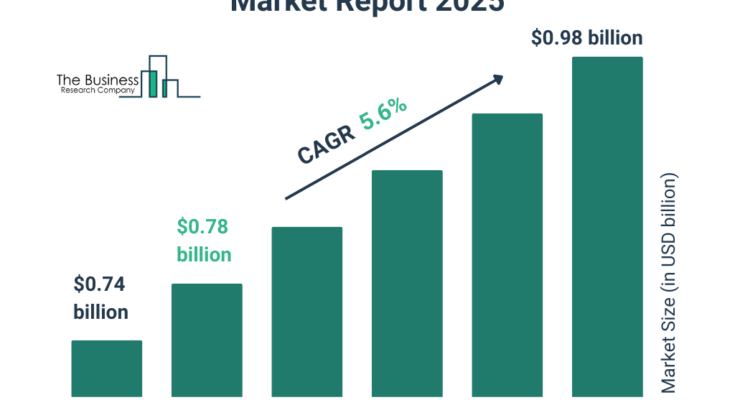

The hot runner temperature controller market size has grown strongly in recent years. It will grow from $0.74 billion in 2024 to $0.78 billion in 2025 at a compound annual growth rate (CAGR) of 5.8%. The growth in the historic period can be attributed to the growing use of composite materials in plastic molding, the growth of injection molding in the food and beverage industry, the growth in consumer electronics production, the demand for high-performance packaging solutions, and the increased use of multi-cavity molds.

The hot runner temperature controller market size is expected to see strong growth in the next few years. It will grow to $0.98 billion in 2029 at a compound annual growth rate (CAGR) of 5.6%. The growth in the forecast period can be attributed to increased automation in molding operations, increasing demand for customized plastic products, rising use of electric injection molding machines, growing demand for miniaturized electronic components, and growing awareness about thermal stability in plastic processing. Major trends in the forecast period include advances in mold design and engineering, integration of cloud-based remote monitoring, AI-powered temperature control algorithms, advanced touch-screen interfaces for controllers, and digital twin technology for virtual mold testing.

Get Your Free Sample of The Global Hot Runner Temperature Controller Market Report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=21482&type=smp

What key drivers have fueled the hot runner temperature controller market’s development over the years?

The rising demand in the automotive industry is expected to propel the growth of the hot runner temperature controller market going forward. The automotive industry is the sector that designs, manufactures, and sells vehicles and their parts. The growing demand in the automotive industry is driven by increasing consumer preference for advanced technologies, including electric vehicles (EVs), autonomous driving systems, and enhanced safety features, along with a shift toward sustainable mobility solutions. A hot runner temperature controller is essential for ensuring consistent temperature regulation in the injection molding process, which improves the quality, accuracy, and efficiency of automotive component manufacturing. For instance, in March 2024, according to the European Automobile Manufacturers Association, a Belgium-based motor vehicle manufacturing association, in 2023, global car production totaled nearly 76 million units, marking a significant 10.2% rise compared to the previous year. Therefore, the rising demand in the automotive industry will drive the hot runner temperature controller market.

What is the segmentation for the hot runner temperature controller market?

The hot runner temperature controller market covered in this report is segmented –

1) By Type: Valve Gate Hot Runner, Open Gate Hot Runner

2) By Output Power: Low (=100kW), Medium (100-500kW), High (>500kW)

3) By Application: Injection Molding, Extrusion, Blow Molding

4) By Distribution Channel: Direct Sales, Indirect Sales

5) By End User: Aerospace, Automotive, Healthcare, Electrical And Electronics, Consumer Goods, Other End Users

Subsegments:

1) By Valve Gate Hot Runner: Hydraulic Valve Gate Controllers, Pneumatic Valve Gate Controllers, Electric Valve Gate Controllers

2) By Open Gate Hot Runner: Sequential Valve Gate Controllers, Manifold Temperature Controllers

Order your report now for swift delivery

Who are the most influential companies in the hot runner temperature controller market?

Major companies operating in the hot runner temperature controller market are Husky Injection Molding Systems Ltd., Barnes Group Inc., Watlow Electric Manufacturing Company, Meusburger Georg GmbH & Co KG, Synventive Molding Solutions Inc., INCOE Corporation, Dynisco Instruments LLC, Hotset GmbH, The Conair Group LLC, Hasco Hasenclever GmbH + Co KG, EWIKON Heißkanalsysteme GmbH, HRSflow S.r.l., GÜNTHER Heisskanaltechnik GmbH, Mastip Technology Limited, Polyshot Corporation, Delta T Systems LLC, Mold Hotrunner Solutions Inc., FISA Corporation, Gammaflux L.P., Shanghai SURE Hot Runner Electrical Co. Ltd.

How will emerging trends drive the hot runner temperature controller market throughout the forecast period?

Major companies operating in the hot runner temperature controller market are focusing on developing products with innovative features such as digital control of inputs to enhance precision, improve energy efficiency, and enable real-time monitoring for optimized performance. Digital control of inputs is the use of digital signals to regulate and monitor the inputs (such as temperature, pressure, or voltage) in a system. This method replaces traditional analog controls, offering more precise, reliable, and easily programmable control. For instance, in February 2024, PCS Company, a US-based plastics manufacturing company, launched the MCS hot runner temperature control systems, which incorporate cutting-edge technology. These systems provide fast control response and flexible zone control, supporting anywhere from 6 to 120 zones. Additionally, they are equipped with Industry 4.0 capabilities, such as virtual network computing (VNC) for remote operation. With integrated advanced diagnostics, including leak and zone detection, these systems ensure reliable and high-performance operation.

What are the major regional insights for the hot runner temperature controller market, and which region holds the top position?

Asia-Pacific was the largest region in the hot runner temperature controller market in 2024. The regions covered in the hot runner temperature controller market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

What Does The Hot Runner Temperature Controller Market Report 2025 Offer?

The hot runner temperature controller market research report from The Business Research Company offers global market size, growth rate, regional shares, competitor analysis, detailed segments, trends, and opportunities.

A hot runner temperature controller refers to a device used in injection molding to regulate the temperature of the hot runner system, ensuring consistent material flow and mold quality. It is used to maintain precise temperature settings in injection molding systems, optimizing material flow, reducing waste, and improving mold performance and part quality.

Purchase the exclusive report now to unlock valuable market insights:

https://www.thebusinessresearchcompany.com/purchaseoptions.aspx?id=21482

With over 15000+ reports from 27 industries covering 60+ geographies, The Business Research Company has built a reputation for offering comprehensive, data-rich research and insights. Armed with 1,500,000 datasets, the optimistic contribution of in-depth secondary research, and unique insights from industry leaders, you can get the information you need to stay ahead.

Our flagship product, the Global Market Model, is a premier market intelligence platform delivering comprehensive and updated forecasts to support informed decision-making.

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: info@tbrc.info

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model